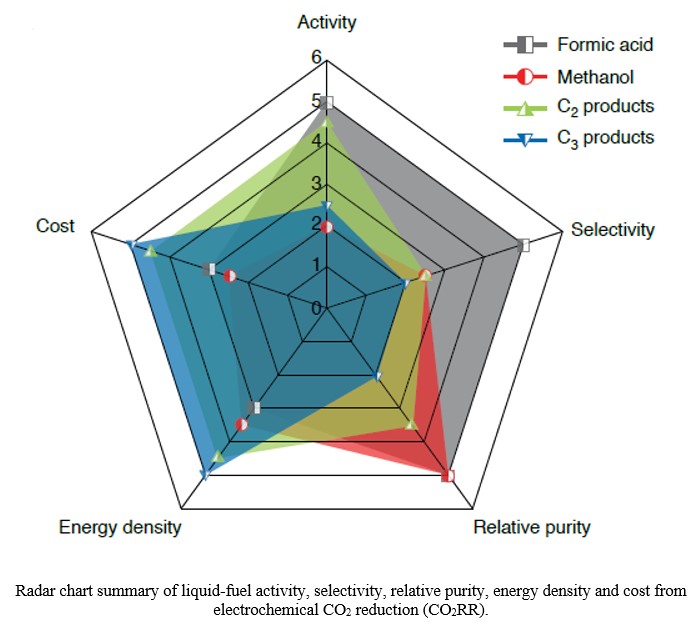

As the renewable electricity price falls continuously, liquid fuels generated from the electrochemical CO2 reduction reaction (CO2RR) are of particular interest due to their high energy densities and ease of storage and distribution. Unfortunately, they are typically formed in low concentrations and mixed with impurities due to the current limitations of traditional CO2 electrolysers as well as CO2RR catalysts. Therefore, the downstream purification process will add an extra layer of cost that greatly harms their economic feasibility for large-scale applications. A Perspective, published in Nature Catalysis (https://www.nature.com/articles/s41929-021-00694-y), proposed different strategies in reactor engineering and catalyst improvement to realize the direct and continuous generation of high-purity and high-concentration liquid fuels from CO2RR electrolysers, allowing this electrochemical route to become more competitive compared with the traditional chemical engineering industry in the future.

Dioxide Materials’ patented unique three-compartment cell is able to produce high-purity and high concentration of formic acid continuously at high current density and energy efficiency. Try our complete formic acid cell or build your own hardware to produce liquid fuels of your interest.