Dioxide Materials Has Developed CO2 Electrolyzers With Record Performance

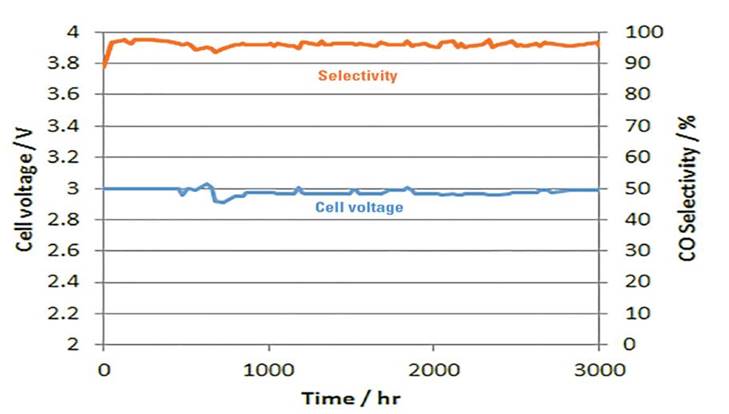

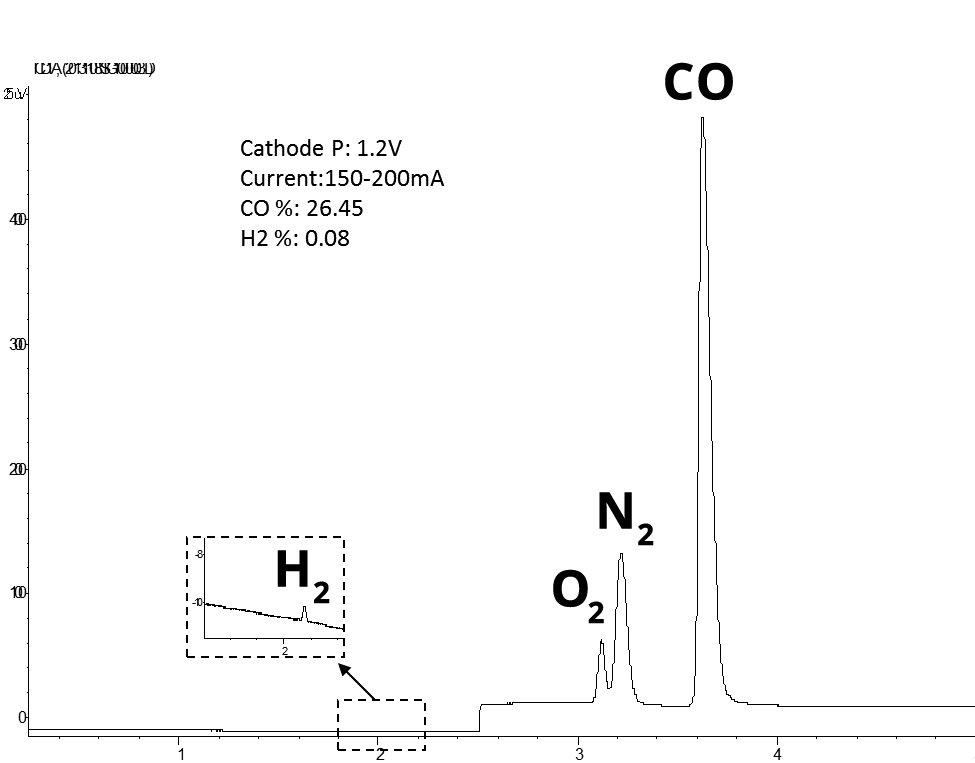

Currents up to 500 mA/cm2 at 3 V

Selectivity (Faraday efficiency) above 95%

Only 6 µV/hr voltage increase, equivalent to a 4 year lifetime

Stable performance demonstrated in 6 month run

Can be integrated with an ethanol fermenter to increase ethanol production

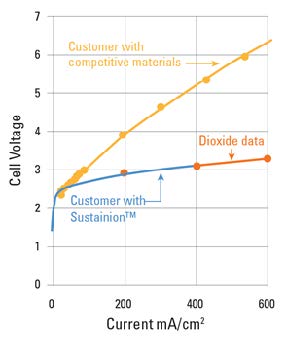

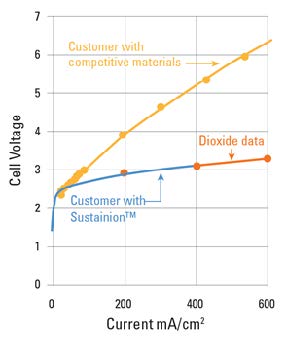

Examples of the Performance Seen With Dioxide Materials’ CO2 electrolyzer

The voltage needed to maintain 200 mA/cm2 at room temperature.

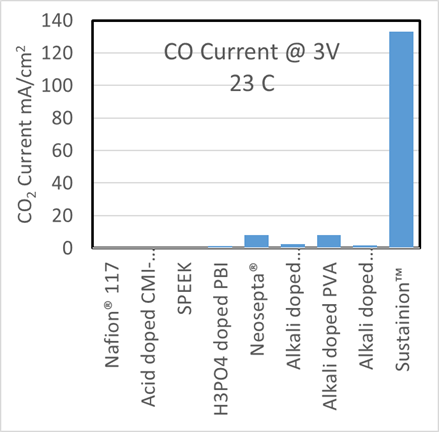

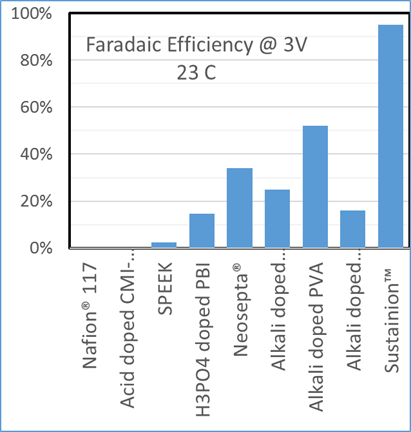

Dioxide Materials’ Sustainion® membranes enable electrolyzers to outperform the competition

Dioxide Materials’ patented catalysts make the process economic

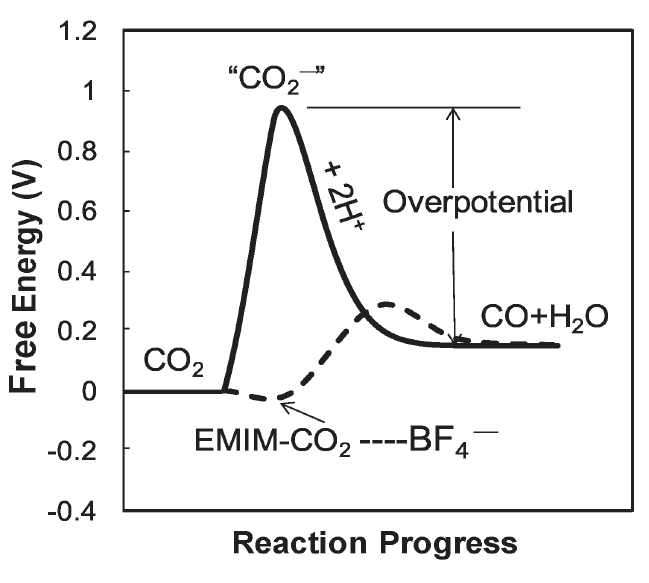

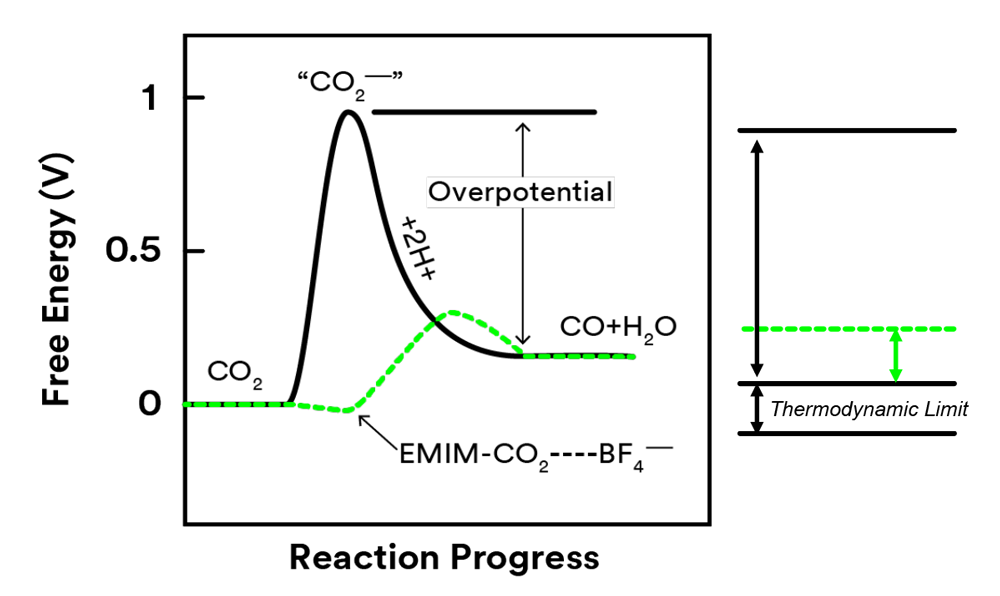

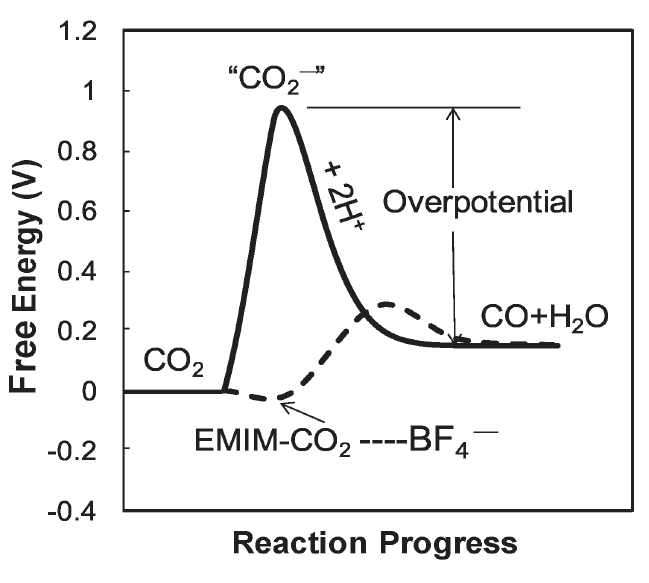

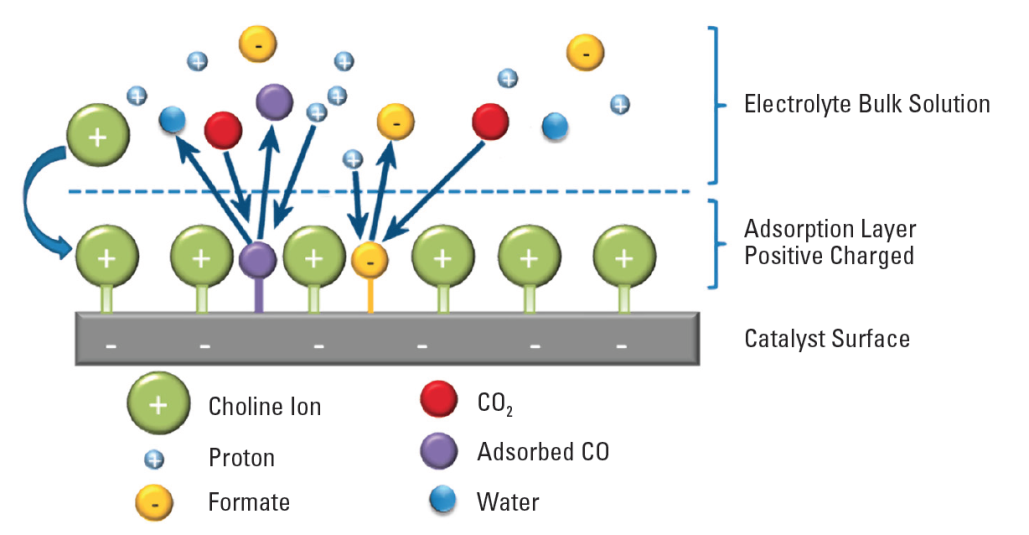

Co-catalyst Lowers the Overpotential

Challenge for electrochemical reduction of CO2

- High overpotential due to the formation of intermediate species

- Low selectivity due to the side reactions

Breakthrough

-

- Combined ionic liquid with Ag metal

- Lowered the overpotential to 0.17V

- Suppressed side reactions

- Improved the selectivity to 98%

Rosen, et al., Science 334, 643 (2011)

Why such good performance?

EMIM creates low barrier pathway

EMIM blocks side reactions

High Selectivity

Dioxide Materials’ Advantages

Better Materials

| Membrane | ASR in 1 M KOH, 60 °C | pH Range</td |

| Sustanion® 37-50 | 0.045 Ω-cm2 | 2-14 |

| Fumasep FAS-50 | 0.37 Ω-cm2 | 0-13 |

| Nafion 115 | 0.52 Ω-cm2 | 0-13 |

| Fumasep FAPQ-375 | 0.83 Ω-cm2 | 0-11 |

| AMI-7001 | 2.0 Ω-cm2 | 0-10 |

| PBI | 8.3 Ω-cm2 | 2-10 |

| Neosepta ACN | >50 Ω-cm2 | 0-8 |

Better Performance