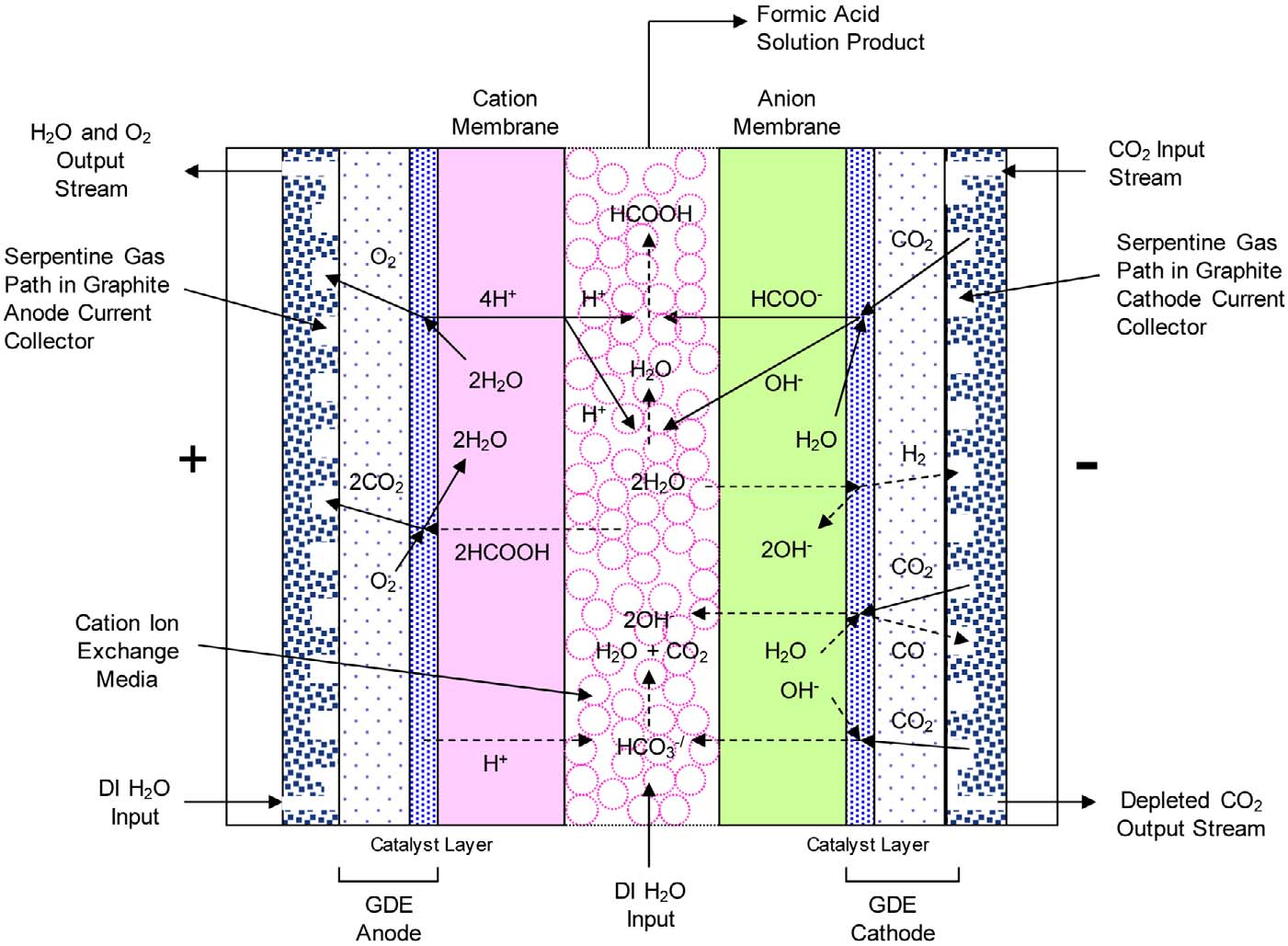

Dioxide Materials has Developed Electrochemical CO2 to Formate/Formic Acid 3 Compartment Cell Design with Record Performance

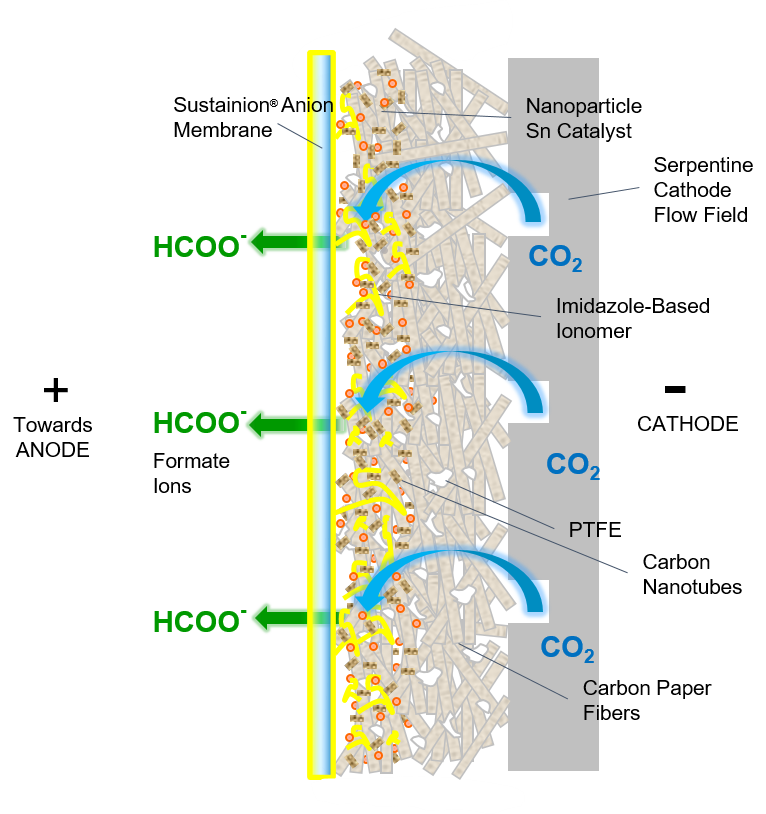

GDE Cathode with Nanoparticle Tin Electrocatalyst and Sustainion® Ionomer

Sustainion® Anion Exchange Membrane

Center Compartment with Strong Acid Media

Anode Side Cation Membrane

Anode with IrO2 Electrocatalyst

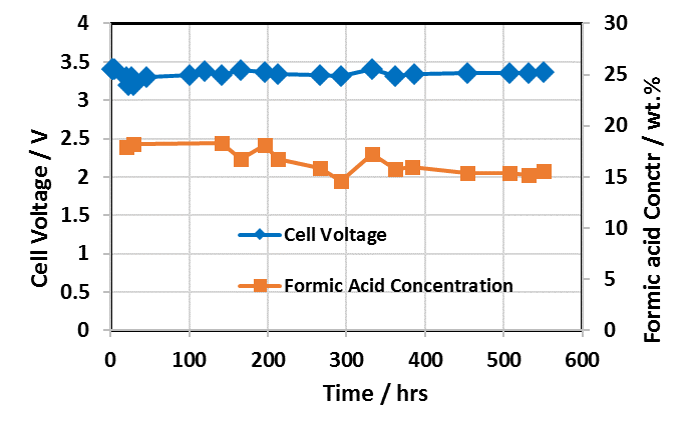

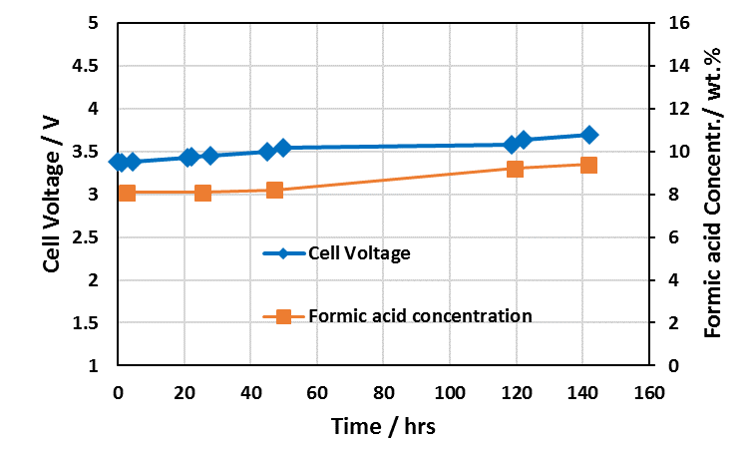

Extended Formic Acid Cell Operating Performance with Dioxide Materials’ Sustainion® Membranes

Cell Run 550 Hours – IrO2 on Carbon Anode

Cell Run 140 Hours – IrO2 on Ti Anode

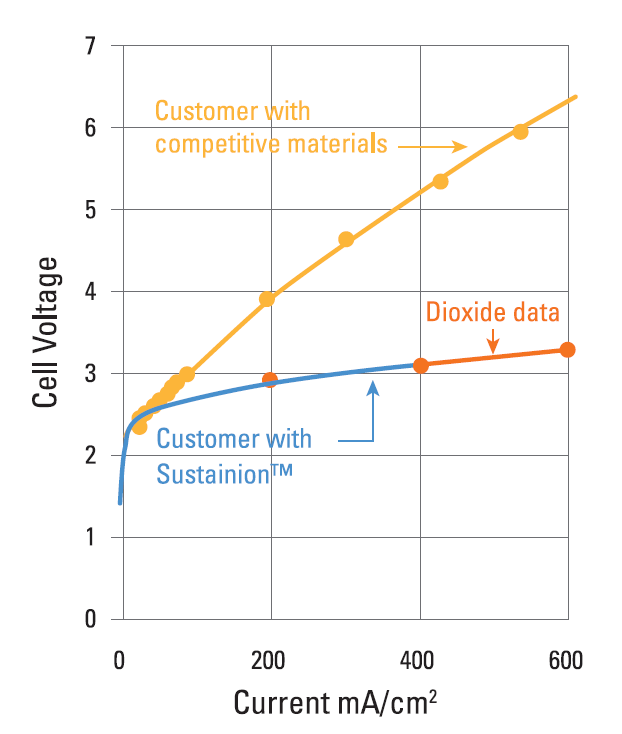

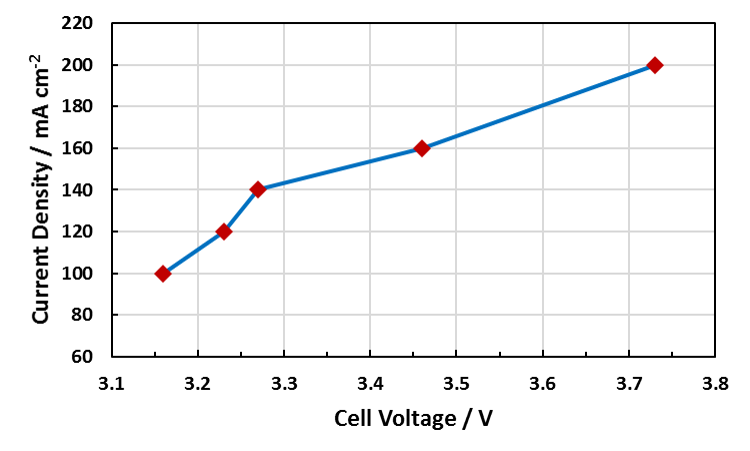

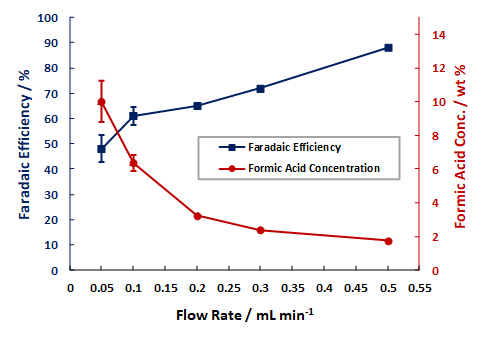

Examples of the Performance Seen With Dioxide Materials’ CO2 to Formic Acid Electrolyzer

Cell Voltage vs. Current Density

Formic Acid FE and Wt% vs. Single Pass Flow Rate

Dioxide Materials’ Patented Catalysts Make the Process Economic

Electrochemical Reduction of CO2 to Formic Acid

Cathode Catalyst Components

GDE Cathode

Tin nanoparticle electrocatalyst, carbon nanotubes, and imidazole-based ionomer

Sustainion® Anion Membrane

Why such good performance?

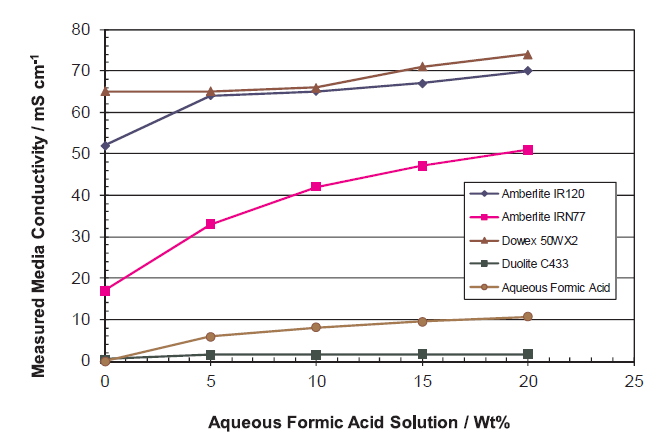

Center Compartment Ion Conductivity

Dioxide Materials’ Advantages

Better Materials

| Membrane | ASR in 1 M KOH, 60 °C | pH Range |

| Sustanion® 37-50 | 0.045 Ω-cm2 | 2-14 |

| Fumasep FAS-50 | 0.37 Ω-cm2 | 0-13 |

| Nafion 115 | 0.52 Ω-cm2 | 0-13 |

| Fumasep FAPQ-375 | 0.83 Ω-cm2 | 0-11 |

| AMI-7001 | 2.0 Ω-cm2 | 0-10 |

| PBI | 8.3 Ω-cm2 | 2-10 |

| Neosepta ACN | >50 Ω-cm2 | 0-8 |

Better Performance