Sustainion® Alkaline Anion Exchange Membrane X37-50 grade T (New)

Price range: $35.00 through $802.00

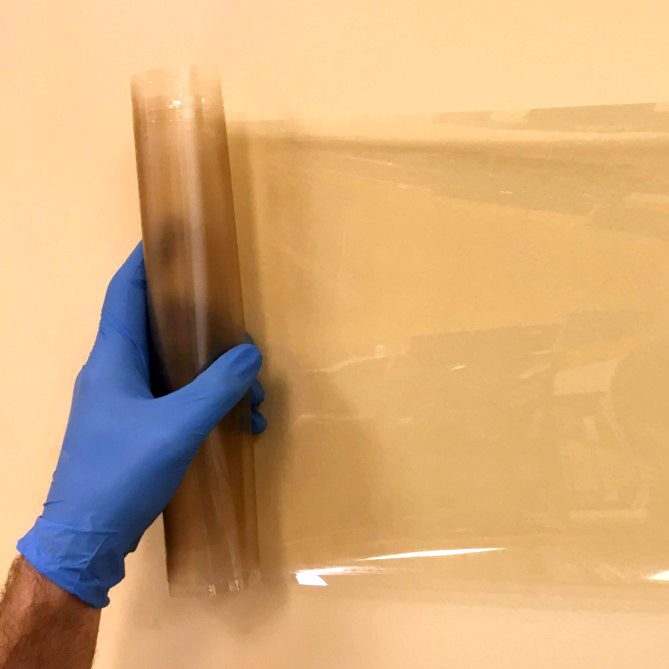

20 cm, x 28 cm sheets of Sustainion® Alkaline Anion Exchange Membrane with PTFE support for easier handleability and greater strength. It is moderately basic and designed for use with supporting electrolyte. Dioxide Materials has optimized it for use in anion exchange membrane water electrolyzers electrolyzers as described in Masel et al. ECS Transactions, 75 (14) 1143-1146 (2016).

See also patents 9,370,773, 9,481,939.

The anion membranes are supplied in dry-chloride form. They consequently have to be converted to the hydroxide form by exposing them to a strong base. Dioxide Materials recommends soaking the membrane in a large bath of 1M KOH for 24 – 48 hours in order to convert the membrane chloride form into the hydroxide form. This activation also helps in strengthening the membrane via crosslinking with KOH as identified by a recent NMR study [19]. Furthermore, during this process the membrane swells.

Note: The membrane is a sandwich structure with a thin porous PTFE layer coated with sustainion 37 on both sides. The PTFE decreases the transport of water in the membrane so they are less efficient in CO2 electrolyzers.

Due to recent high customer demand and supply chain issues, you may experience a longer wait for this product. Dioxide Materials team is making the best effort to resolve it quickly. Thanks for your patience and support!

Description

20 c x 28 cm sheets of Sustainion® Alkaline Anion Exchange Membrane with PTFE support for easier handleability and greater strength. It is moderately basic and designed for use with supporting electrolyte. Dioxide Materials has optimized it for use in anion exchange membrane water electrolyzers as described in Masel et al. ECS Transactions, 75 (14) 1143-1146 (2016).

See also patents 9,370,773, 9,481,939.

The anion membranes are supplied in dry-chloride form. They consequently have to be converted to the hydroxide form by exposing them to a strong base. Dioxide Materials recommends soaking the membrane in a large bath of 1M KOH for 24 – 48 hours in order to convert the membrane chloride form into the hydroxide form. This activation also helps in strengthening the membrane via crosslinking with KOH as identified by a recent NMR study. Furthermore, during this process the membrane swells.

Note: The membrane is a sandwich structure with a thin porous PTFE layer coated with Sustainion® 37 on both sides. The PTFE decreases the transport of water in the membrane so they are less efficient in CO2 electrolyzers.

You may also like…

-

Anode electrode for carbon dioxide electrolyzer

Price range: $206.00 through $2,512.00 Add to Cart This product has multiple variants. The options may be chosen on the product page -

Sale!

Build your own 5 cm2

Original price was: $2,702.00 – $3,092.00Price range: $2,702.00 through $3,092.00. Price range: $2,668.00 through $3,058.00Current price is: $2,668.00 – $3,058.00Price range: $2,668.00 through $3,058.00. Add to Cart

Electrolyzer Hardware -

Cathode electrode for carbon dioxide electrolyzer

Price range: $59.00 through $1,128.00 Add to Cart This product has multiple variants. The options may be chosen on the product page