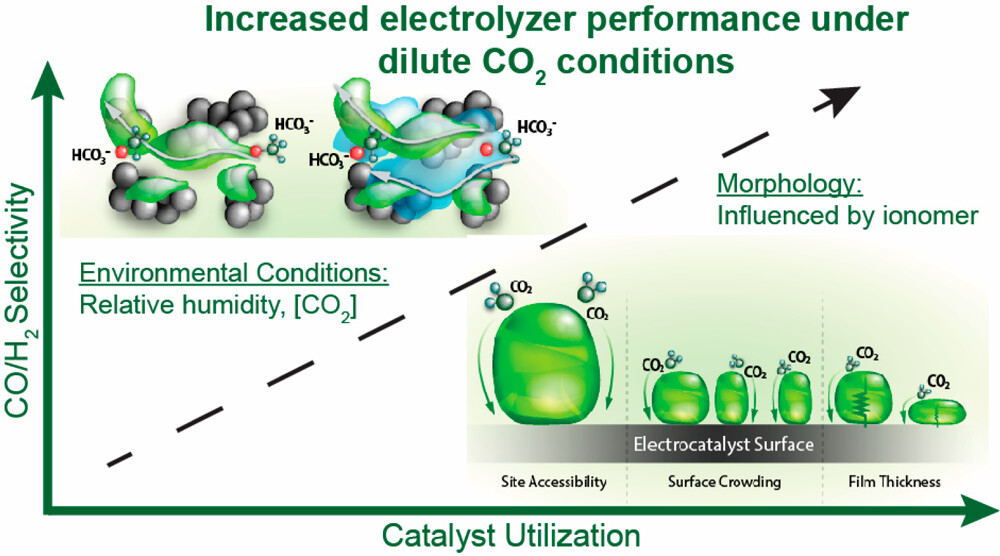

While low-temperature electrochemical CO2 reduction has demonstrated high CO selectivity with pure CO2 in zero-gap anion exchange membrane CO2 electrolyzer, there is a significant knowledge gap regarding its performance in environments with CO2 concentrations below 30%. This is a critical aspect for integrating these devices into practical applications where CO2 is captured from point sources. To bridge this gap, Henckel and her colleagues at National Renewable Energy Laboratory (NREL) and at Dioxide Materials explored the influence of ionomer chemistry and cell operating conditions on the CO selectivity at low CO2 concentrations (doi.org/10.1021/acsenergylett.4c01224). The results showed that maintaining CO2 concentrations above 20% and cathode relative humidity (RH) at least 50% consistently yielded CO/H2 selectivity exceeding 95%, regardless of the ionomer used. However, at 10% CO2, achieving the same level of selectivity required a cathode RH of 95% to create an electrode morphology that facilitated high catalyst utilization.

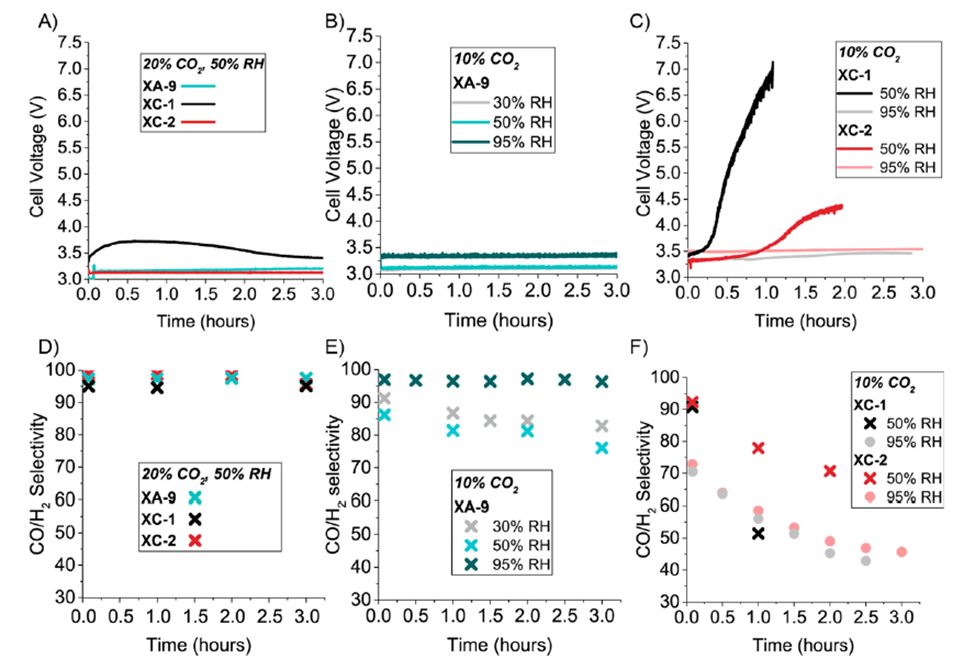

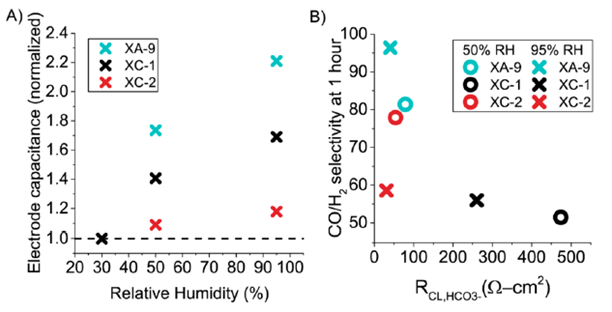

Figure 1 shows the cell performance of a 25cm2 CO2 electrolyzers and CO selectivity at various conditions. In all cases, Sustainion anion exchange membrane was sandwiched between an IrO2 anode and Ag cathode. Ag cathode was made with three different ionomers, XA-9, XC-1 and XC-2. XA-9 ionomer outperformed than the other two under various conditions. Specifically, at 10% CO2, only Ag cathode made with XA-9 could maintain 95% CO selectivity with a cathode RH of 95%. Detailed investigations reveal that the ionomer’s hydrophobicity/hydrophilicity significantly influences water distribution within the catalyst layer. A strong correlation exists between the increase in relative electrode capacitance with relative humidity and the hydrophobicity of the ionomers (Figure 2), with XA-9 exhibiting the highest hydrophobicity, followed by XC-1 and XC-2.

Figure 1 Time versus cell voltage for a 25 cm2 cell operating at 200 mA/cm2 for (A) XA-9, XC-1, and XC-2 at 20% CO2 and 50% RH, (B) XA-9 at 10% CO2 and 30, 50, and 95% RH, and (C) XC-1 and XC-2 at 10% CO2 and 50 and 95% RH. (D−F) Corresponding CO/H2 selectivities for data in (A−C).

Figure 2. (A) Relative humidity (%) versus normalized electrode capacitance (all values are normalized to capacitance at 30% RH for respective electrodes). (B) Ionic resistance of the catalyst layer (RCL,HCO3− (Ω cm2)) versus CO/H2 selectivity at 1 h at 200 mA/ cm2 for XA-9, XC-1, and XC-2 at 10% CO2 and 50% and 95% RH.